- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

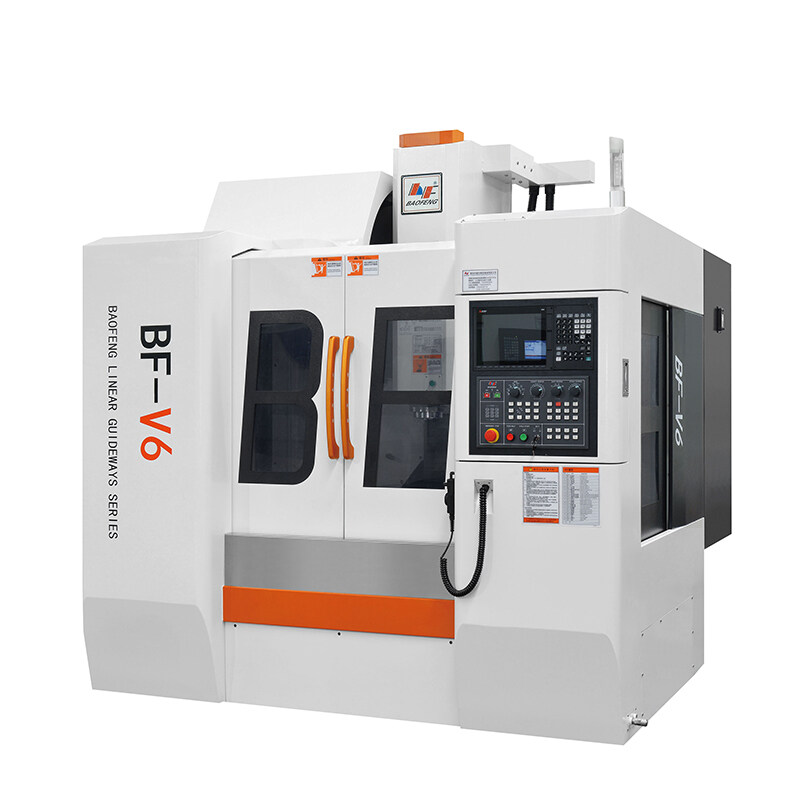

BAOFENG V6 Linear way machining center

With the rigidity, stability, high speed and high precision moving parts, it could accept high inertia gravity and even a long time processing. The strongest column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine. The spindle vibration is smaller than most popular V4 vibration standard, providing better surface processing performance.. The fastest tapping speed can reach 6000 rpm and the smallest tooth can attack M1.2

SPECIFICATION

| Travel | X-axis | mm | 600 |

|---|---|---|---|

| Y-axis | mm | 500 | |

| Z-axis | mm | 450 | |

| Spindle nose to table | mm | 150-600 | |

| Spindle center to column | mm | 470 | |

| Worktable | Table size | mm | 720-450 |

| Maximum load on table | kg | 400 | |

| T-slot | No. | 5-18*90mm | |

| Controller | Mitsubishi System | M80 | |

| Spindle | Driving type | Direct drive | |

| Spindle speed | rpm | 12000 | |

| Spindle taper and specifications | BT40 | ||

| Spindle motor power | kw | 7.5/11-10000rpm(S1/S2 30min) | |

| Spindle torque | Nm | 47.7/70(S1/S2 30min) | |

| 3 axis motor | X/Y/ Z axis motor power | kw | 2.0/2.0/3.0 |

| X/Y/ Z axis motor torque | Nm | 13.7/4722.5/64 | |

| X/Y/Z rapid feed | m/min | 48/48/48 | |

| Machine accuracy(X/Y/Z) | Positioning accuracy | mm | 0.003/300 |

| Repeat positioning accuracy | mm | 0.002/300 | |

| Machine | Dimension | mm | 2200X2770X2730 |

| Weight | Kg | 4200 |

Standard Accessories:

- MitsubishiM80 5/11 KW-10000rpm+2.0/2.0/3.0KW

- Workpiece blowing system

- Cutting fluid cooling system

- Central lubrication systemHandwheel

- Heat exchanger

- Chip flushing system

- Guideway Cover

- Fully enclosed metal cover

- Spindle oil coolant

- Handwheel

- Working light

- Alarming light

MAIN PARTS BRAND

| NO. | Item | Brand | Origin | Note |

|---|---|---|---|---|

| 1 | Controller | Mitsubishi | Japan | M80 |

| 2 | Spindle motor | Mitsubishi | Japan | 7.5/11 KW-10000rpm |

| 3 | X/Y/Z motor | Mitsubishi | Japan | 2.0/2.0/3.0KW |

| 4 | Spindle | BAOFENG | Joint Venture | BT40 12000rpm |

| 5 | X/Y/Z screw | NSK | Japan | 16mm |

| 6 | X/Y/Z linear guideway | Rexroth | Germany | ball |

| 7 | Bearing | NSK/FAG | Japan/Switzerland | P4 |

| 8 | Coupling | R+W | Germany | EK2/24/20 |

| 9 | Cylinder system | Hinaka | Taiwan | BPF-10U12N110FA |

| 10 | Spindle oil coolant | Rucol | Joint Venture | RCO |

| 11 | Heat exchanger | Rucol | Joint Venture | RC-25 |

| 12 | Cutting fluid pump | Luikar | Joint Venture | LDPB4V/2V-30 |

| 13 | Three point combinations | Mindman | Taiwan | MAP3000 |

| 14 | Pneumatic components | Mindman | Taiwan | AC3000L |

| 15 | Main contactor | Mitsubishi | Japan | S-T80 |

| 16 | Circuit Breaker | Mitsubishi | Japan | NFC60-SMX |

| 17 | Relay | Omron | Japan | RU2S-D24 |

| 18 | Switching power supply | Omron | Japan | LRS-150-24 |

| 19 | Central lubrication system | BAOTN | Taiwan | BT-C2P |

| 20 | Handwheel | SY | Taiwan | N-210A4X5P4C-DGBK |

| 21 | Wire | SY | Taiwan | Special oil proof material |

*The manufacturer reserves the right to change the brand due to delivery time/technical improvement and other reasons.

FEATURES

- High rigidity moving parts with lightweight design for high speed and high precision parts processing, faster and more powerful parts processing machine.

- High strength gray casting iron machine body remains a high rigidity and stability even a long time processing.

- Special large span structure column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine.

- V1 vibration standard of direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

- Heavy loading ball linear guide in 3 axis, max rapid feed speed 48 m/min. The fastest tapping speed can reach 6000 rpm, the smallest tooth can attack M1.2.

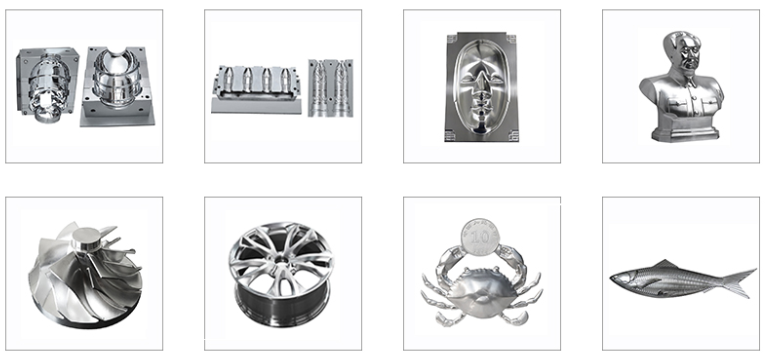

APPLICATION

It can continuously complete drilling, milling, tapping, boring, reaming and other machining processes by once clamping, and can complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently. This series of machine is widely used for mass production of small and medium-sized cabinets, covers, panels, shells and plates in high-precision molds, automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products and machinery manufacturing industries.

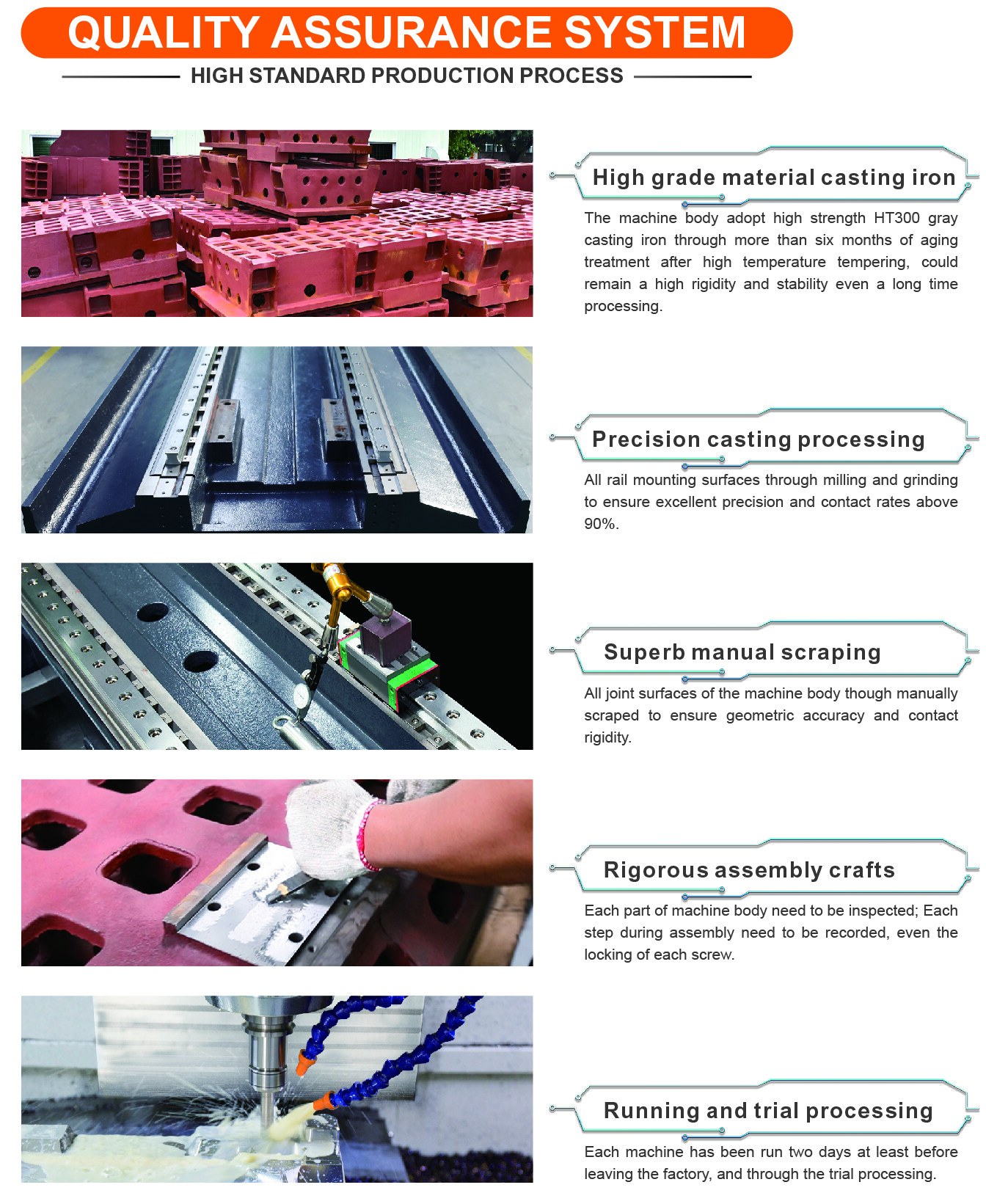

QUALITY SUPERVISION

CERTIFICATES

CASE CUSTOMER

PACKAGING & SHIPPING

FAQ

1. How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing, we will choose the most suitable machines for you.

2. What're the main products of your company?

A: We specialized in all kinds of machines, such as Vertical Machining Center, Double Column Machining Center, Drilling and Tapping CNC Machining Center, Engraving and Milling Center, etc.

3. Where is our factory located? How can I visit there?

A: Our factory is located in Dongguan City, Guangdong Province, China. You are warmly welcome to visit us.

4. What are your trade terms?

A: FOB, CFR, and CIF are all acceptable.

5. What are the Payment Terms?

A: Generally, T/T,30% initial payment when order,70% balance payment before shipment (This can be negotiated specifically); Irrevocable LC at sight.

6. What's the MOQ?

A: 1 set.